भूमि ही पूजनीयः

The earth deserves worship!

As our shared home, Earth deserves reverence, respect, and protection

due to its vital role in sustaining life, breathtaking beauty, and profound

cultural and spiritual significance.

due to its vital role in sustaining life, breathtaking beauty, and profound

cultural and spiritual significance.

Sakariya Mines & Minerals, a subsidiary of the Sakariya Group, Ahmedabad, India specializes in vertical mineral exploration. It is presently holding two Tanzanian registered junior exploration companies: Grapeak Miners (TZ) Limited and Sakariya Gold (TZ) Limited. The group has successfully acquired 15 prospecting licenses for gold and associated metals, as well as 7 prospecting licenses for graphite and battery minerals. This aligns with our vision to establish a robust presence for the Sakariya Group in Tanzania.

Projects

In the field of mineral exploration Sakariya Group stands out as a significant player boasting a substantial land parcel spanning an expansive area of approximately 364 sq. km in Tanzania. Significantly, the gold and associated metals prospecting licenses held by the group are strategically positioned within the well-known Lake Victoria Greenstone Belt in northern Tanzania, while, the prospecting licenses for graphite and battery minerals are located in the Neoproterozoic Mozambique Mobile Belt (NMMB), extending from North to South on the eastern side of the country.

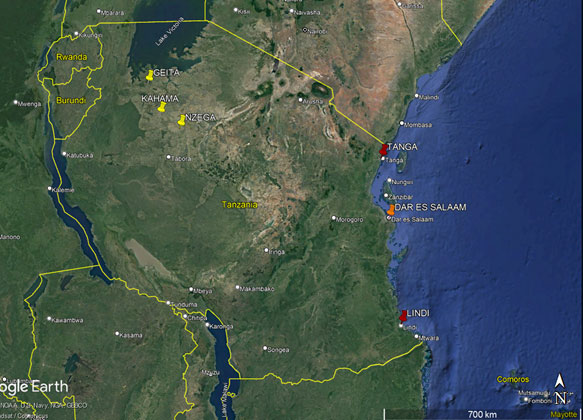

The gold prospecting licenses are scattered in and around Nzega, Kahama and Geita towns where as the graphite licenses are in the vicinity of the port towns Tanga and Lindi. Tanga is in northern Tanzania, near to the border with Kenya and Lindi is in southern Tanzania, near to the border with Mozambique.

Geographical presence of Sakariya in Tanzania. (Exploration work for gold and associated metals are limited to the places marked in yellow; places marked in red are indicating our prospecting licenses for graphite and battery minerals.)

Orogenic gold deposits are well known sources of metallic gold worldwide. Although these deposits occur throughout the geological time, the Late Archean (2.8–2.55 Ga) period was especially favourable for orogenic gold-vein formation. The Lake Victoria Greenstone Belt- a cluster of gold occurrences in the southern and eastern part of Lake Victoria, Tanzania; is a quintessential example of such Late Archean orogenic gold deposit. The gold mineralization in Lake Victoria Greenstone Belt is associated with granite-greenstone rocks which occur as narrow belts and trend approximately E-W in the northern part of Tanzania Craton.

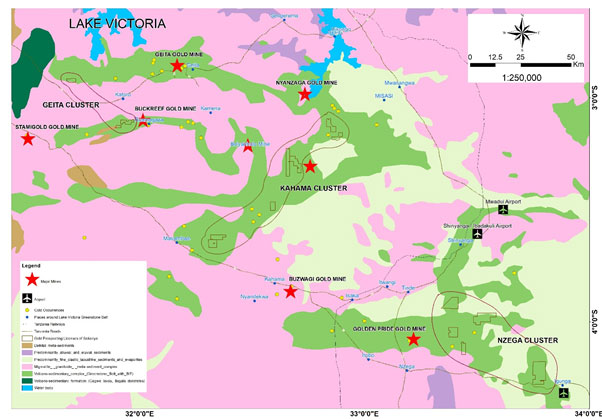

Location of Prospecting Licenses for gold and associated metals in Lake Victoria Greenstone Belt

(Source: Tanzania Mining Cadastre eGov Portal)

The Lake Victoria Greenstone Belt rocks are divided into six major greenstone belts: Sukumaland Greenstone Belt, Nzega Greenstone Belt, Iramba Sekenke Greenstone Belt, Shynianga Malita Greenstone Belt, Kilimafedha Greenstone Belt and North Mara Greenstone Belt. All of these belts share the same lithostratigraphic status and nomenclature.

Sakariya owns a massive exploration land package of around 290 sq.km area for its 15 prospecting licenses which are positioned in Sukumaland Greenstone Belt and Nzega Greenstone Belt for gold and associated metals along with the world-famous mining entities’ assets like Bulyanhulu (Barrick Gold Corp), Geita (AngloGold Ashanti), Buckreef (Tangold Corp), Nyanzaga (Orecorp).

All these prospecting license areas are well connected

from nearest towns/ villages & airports. There are

world-famous mining companies’ assets in the vicinity of

license areas along with on-going active small-scale mining

operations around it and operational gold process

plants of different capacities are also there.

Sakariya owns a massive exploration land package of around 290 sq.km area for its 15 prospecting licenses which are positioned in Sukumaland Greenstone Belt and Nzega Greenstone Belt for gold and associated metals along with the world-famous mining entities’ assets like Bulyanhulu (Barrick Gold Corp), Geita (AngloGold Ashanti), Buckreef (Tangold Corp), Nyanzaga (Orecorp).

Current activities around the Prospecting Licenses for gold and associated metals (Source: Tanzania Mining Cadastre eGov Portal)

The exploration program in the Lake Victoria Greenstone Belt prospecting licenses was initiated with a good deskwork and further followed by reconnaissance field visit and proper field work. Setting up the base-camps in Kahama and Nzega town, we have already executed geological mapping in 25000 scale, soil sampling in 200 by 200-meter grid in all the license areas. Based on these activities, couple of potential areas has been selected to execute ground magnetic survey, trenching and soil sampling in a close spaced manner. Detail geological mapping at 2000 scale in these potential areas has also been initiated and IP-resistivity survey is under planning.

This fast paced and effective positive approach from the highly skilled technical team has encouraged Sakariya management to explore the possibilities for turning the potential areas into mining assets, in all extent.

Graphite and Battery minerals

Graphite and battery minerals play crucial roles in the development and production of batteries, which are essential components in various industries, particularly in the rapidly growing electric vehicle (EV) market and renewable energy sector, resulting in securing a stable supply of these commodities.

The viable economic world-class deposits of graphite form in two geological settings. They are either Archean or Neoproterozoic metamorphic belts. There are reported occurrences of graphite in the Neoproterozoic Mozambique Mobile Belt (NMMB) (MB; Holmes, 1951) in Tanzania, stretching from north to south in the eastern side of the country. The NMMB, also known as the “Pan-African Gems or Graphite Belt”, is essentially comprised of medium to high-grade gneisses and large granitoid bodies.

Location of Prospecting Licenses for graphite and battery minerals in Tanga region (Source: Tanzania Mining Cadastre eGov Portal)

We are having five licenses at Tanga, near the border with Kenya (North-eastern part of Tanzania).

The prospecting licenses at Tanga region are at a distance of 60 k.m. from port town Tanga. The terrain in this area is predominantly undulating. Our dedicated team of geologists and geo-technicians has been engaged in systematic exploration program by setting camp at Maramba, a local village at a distance of 5 k.m. from the concession area.

Current activities around the Prospecting Licenses for graphite and battery minerals (Source: Tanzania Mining Cadastre eGov Portal)

Reconnaissance field visit was followed after a good desktop study. Geological mapping at 1:20000 and 1:5000 scale was conducted and the graphite band has been mapped at 1:2000 scale. Geo-chemical analysis has shown interesting result in terms of total graphitic carbon. Pitting work is also being carried out to constrain the boundary of the inferred graphitic schist with other lithological unit as well as to further delineating multiple graphitic schist bodies within the inferred graphitic schist zone.

The commendable work progress in the concessions of Tanga region led the management to conduct a preliminary feasibility study on the logistics and transportation and facilities at the possible ports of exit of Tanga, Dar es Salaam and Mombasa.

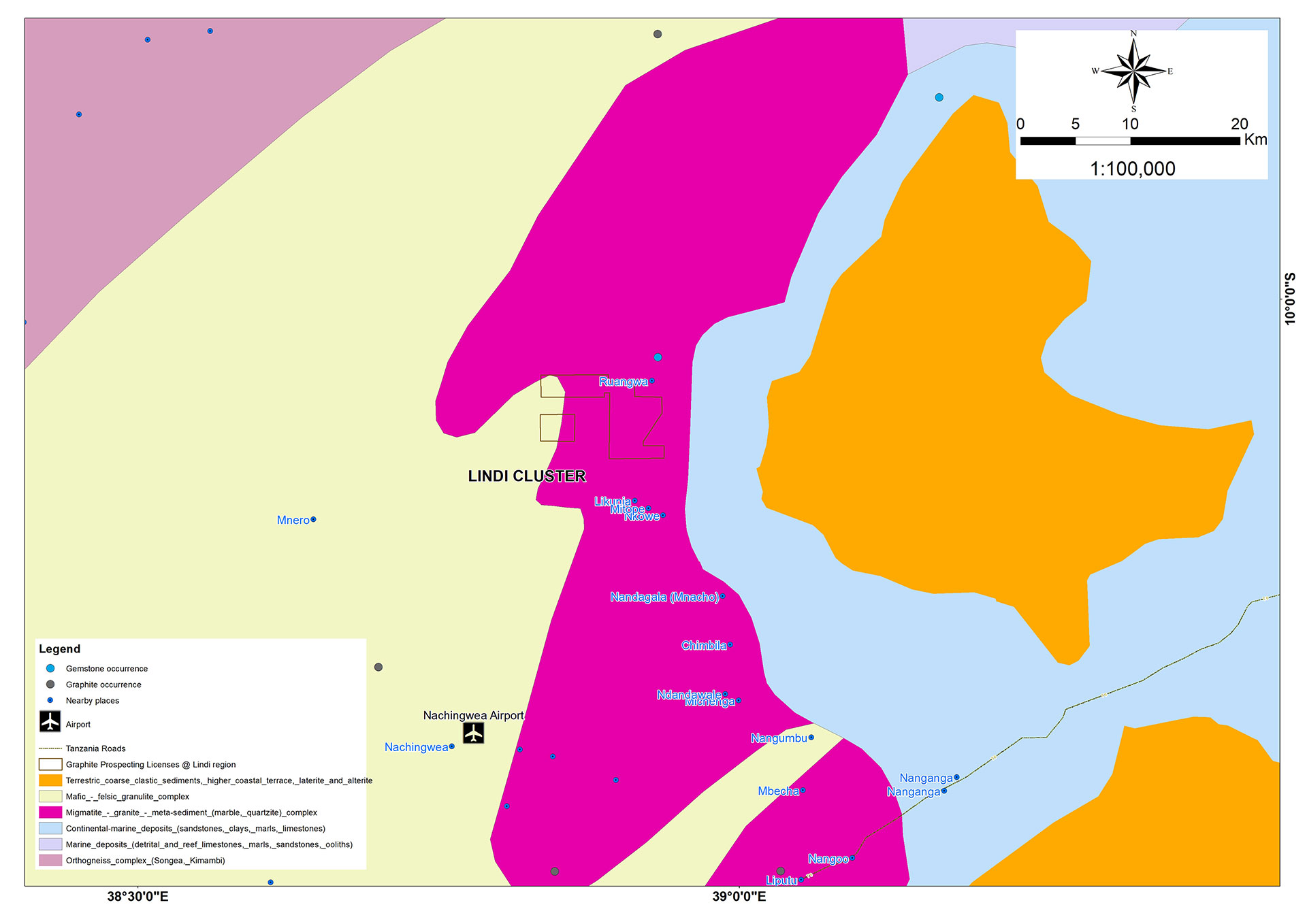

Location of Prospecting Licenses for graphite and battery minerals in Lindi region (Source: Tanzania Mining Cadastre eGov Portal)

Lindi Cluster has 2 prospecting licenses for graphite and battery minerals. Around these 2 license areas, there are many granted prospecting licenses of another companies like Volt Resources, Uranex, Lindi Jambo etc.

This area is almost a plain, grassy land. Desktop study and reconnaissance field visit to these 2 licenses has already been organized. During this field program, the team was engaged to validate respective deskwork.

Current activities around the Prospecting Licenses for graphite and battery minerals (Source: Tanzania Mining Cadastre eGov Portal)

Exploration activities with proper planning will be initiated in this cluster after getting affirmative signal from Sakariya management.

Field works at a glance

Geological mapping

Geological mapping in all our concessions were conducted in two phases. During the reconnaissance stage, a representative map was prepared where only major litholigacal units, mappable in a large scale (1:25000), were mapped. Grab samples were also collected from the outcrops. These samples were further gone through geo-chemical analysis in reputed laboratory in Mwanza, Tanzania.

Following the reconnaissance geological survey, a detailed geological mapping program was taken into account.

Soil geochemical survey

Soil sampling in our Lake Victoria Greenstone Belt concessions, i.e., for gold and associated metals were carried out in two stages: a first stage of sampling with 200m x 200m grid spacing and a second stage of sampling with 100m x 100m grid spacing.

This two-phase approach is common in geological exploration to efficiently cover a large area during the initial reconnaissance and then focus on detailed analysis in specific locations. The combination of geological mapping and geochemical analysis is crucial for assessing the mineral potential of the concessions.

It’s important to note that the success of such exploration efforts depends on the accuracy of mapping, the quality of sample collection, and the reliability of laboratory analyses. The information gathered through these processes can guide further exploration, potentially leading to the discovery of valuable mineral deposits.

Regolith mapping

Regolith mapping was also taken into account for the prospecting licenses related to gold and associated metals.

Ground Magnetic Survey

Based on the results of geological mapping, soil geochemical survey, this survey was planned and carried out with two Evimag and three G-857 magnetometers, in prioritized concessions.

The goal of a ground magnetic survey is to measure variations in the Earth’s magnetic field caused by different magnetic properties of rocks and minerals. This information helps geologists identify geological structures, map subsurface rock types, and potentially locate mineral deposits, including gold. Combined maps were prepared from the ground magnetic data, i.e., Analytical Signal map, Total Magnetic Intensity (TMI) map etc.

Field team involved in geological mapping (fig: a, b, c, d); Team member pointing out box work and sulphide mineralization in grab sample (fig: e); Team member pointing sulphide mineralization in grab sample (fig: f); Team member showing a sample of graphitic schist (fig: g)

Field team involved in soil sampling (fig: h, i, j); Team member inspecting grab sample with pocket lens during fieldwork (fig: k)

Trenching

Trenching is a common method employed in gold exploration to assess the subsurface mineralization by collecting samples from shallow excavations. This method allows geologists to obtain a more detailed understanding of the distribution and grade of gold within the geological structures of interest.

Based on the integration of soil geochemical data with regolith, geological and ground magnetic data, trenching was planned to identify potential source rocks, in prioritized concessions.

Our in-house geologists and geo technicians have successfully planned and executed trench design and excavation, sampling, mapping and geological interpretation. These data sets will be integrated with the assay results for further exploration activities.

Trenching provides a cost-effective way to gather valuable information about the near-surface geology and gold distribution. It is often used in the early stages of exploration to guide subsequent phases of work.

Pitting

Pitting provides valuable information about the underlying geology, including the types of rocks, alteration zones, and potential mineralization. It is generally a cost-effective method compared to drilling, especially in the early stages of exploration. It allows for the rapid collection of geological and geochemical data over a larger area, helping exploration teams prioritize and plan further, more targeted exploration activities.

Pitting activity was taken into account by the in-house technical team in prioritized concessions to identify zones of alteration, which are often associated with mineralization. Certain types of alterations, such as silicification, sericitization, or chloritization, can be visually recognized in pit exposures, providing important clues about the mineralization style and potential deposit types.

Another purpose of pitting was to intersect known mineralized zones or areas of interest as well as to inspect and study the exposed rock formations, soil profiles, and geological structures. Samples collected from the walls and bottoms of pits were analysed for their geochemical content.

Excavated trench (fig: l); Trench sampling at certain interval (fig: m); Team members involved in trench sampling and mapping (fig: n); Team members involved in acquiring data from pit (fig: o, p); Team members supervising pitting activity (fig: q); Safe guarding the ongoing pit (fig: r); Team members visiting artisanal miners’ working around concession area (fig: s)

Team involved in reconnaissance field visit (fig: t, u, v); Technical team of Sakariya paying a visit to an active mining lease (ML) in Lake Victoria Greenstone Belt (fig: w); Team members engaged in discussion during fieldwork (fig: x); Team members inspecting an abandoned old pit around the concession area (fig: y); Technical team members paying a visit to active small-scale miners’ working around concession area (fig: z).

Drilling

Core drilling is the most commonly used method in mineral exploration in advanced stage for obtaining detailed information about the subsurface geology and potential mineral deposits. By extracting cylindrical cores of rock underneath the Earth’s surface, core drilling provides a wealth of data that geologists can analyse both visually and through advanced laboratory techniques.

Drill core samples provide valuable information about the geological formations, mineral composition, structure, and other characteristics of the subsurface. Analysis of these core samples helps geologists and mineralogists determine the presence, quality, and extent of mineral deposits, which is essential for making decisions regarding further exploration, resource estimation, and mining operations.

Drilling activity was taken into account by the in-house technical team after integrating all the previous exploration data. Borehole planning, determination of borehole angle, tentative estimation of meterage and other things were planned & evaluated by the in-house technical team.

Drill rig in action (fig: aa); Technical team of Sakariya at drill site (fig: ab); Team member showing drill core sample (fig: ad, ae); Drill cores stacked in core box (fig: ac, af)